Industry

Share

Discover how GEODIS transformed their warehouse operations with the Exotec® Skypod® system. With this technology, three employees can now process over 750 lines per hour from three picking stations, ensuring rapid order fulfillment operations and adaptability for an unpredictable future.

About GEODIS

GEODIS is a leading global logistics provider and is ranked No. 6 in its sector across the world. Widely regarded as one of the foremost leaders in all aspects of the supply chain, GEODIS has a direct presence in 60+ countries (and a global network covering nearly 170 countries) and more than 49,400 employees. The logistics leader is committed to serving people by delivering their goods all around the world with innovative, sustainable, and ethical logistics. To learn more about GEODIS click here.

The Challenge

GEODIS’ warehouse in Nashville is responsible for fulfilling orders for multiple brands with a diverse range of products that is always changing. In order to achieve their objectives, GEODIS realized the need for a high-performing, flexible, and efficient order fulfillment system.

A high-performing system was required to process thousands of orders each day while also adapting to urgent order requests. Given their lack of direct insight into their clients’ SKU changes, as well as projections for peak seasons and long-term growth, GEODIS required a highly flexible system. High on their checklist was a system adept at seamlessly managing orders from various distribution channels, with the agility to rapidly scale throughput and storage capacity while avoiding unnecessary costs or operational disruptions.

Matt Street, GEODIS’ Vice President and General Manager of eLogistics, stated, “We don’t always know the specifics of what we’re going to receive from our customers, so we had to design with flexibility in mind and Exotec® certainly gave us that.”

Due to the ongoing labor shortage, GEODIS needed a solution to automate the laborious and inefficient tasks associated with manual order picking. These tasks included walking long distances each day and lifting heavy items, which were time-consuming and strenuous for employees. GEODIS was in search of a solution that would not only alleviate these issues, but also promote a more employee-friendly and productive work environment.

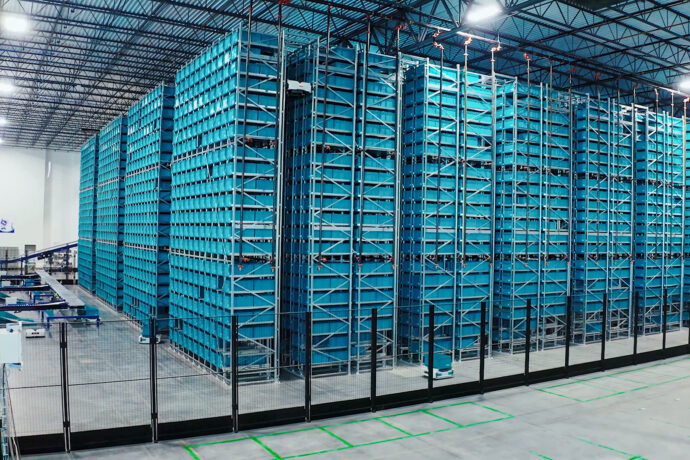

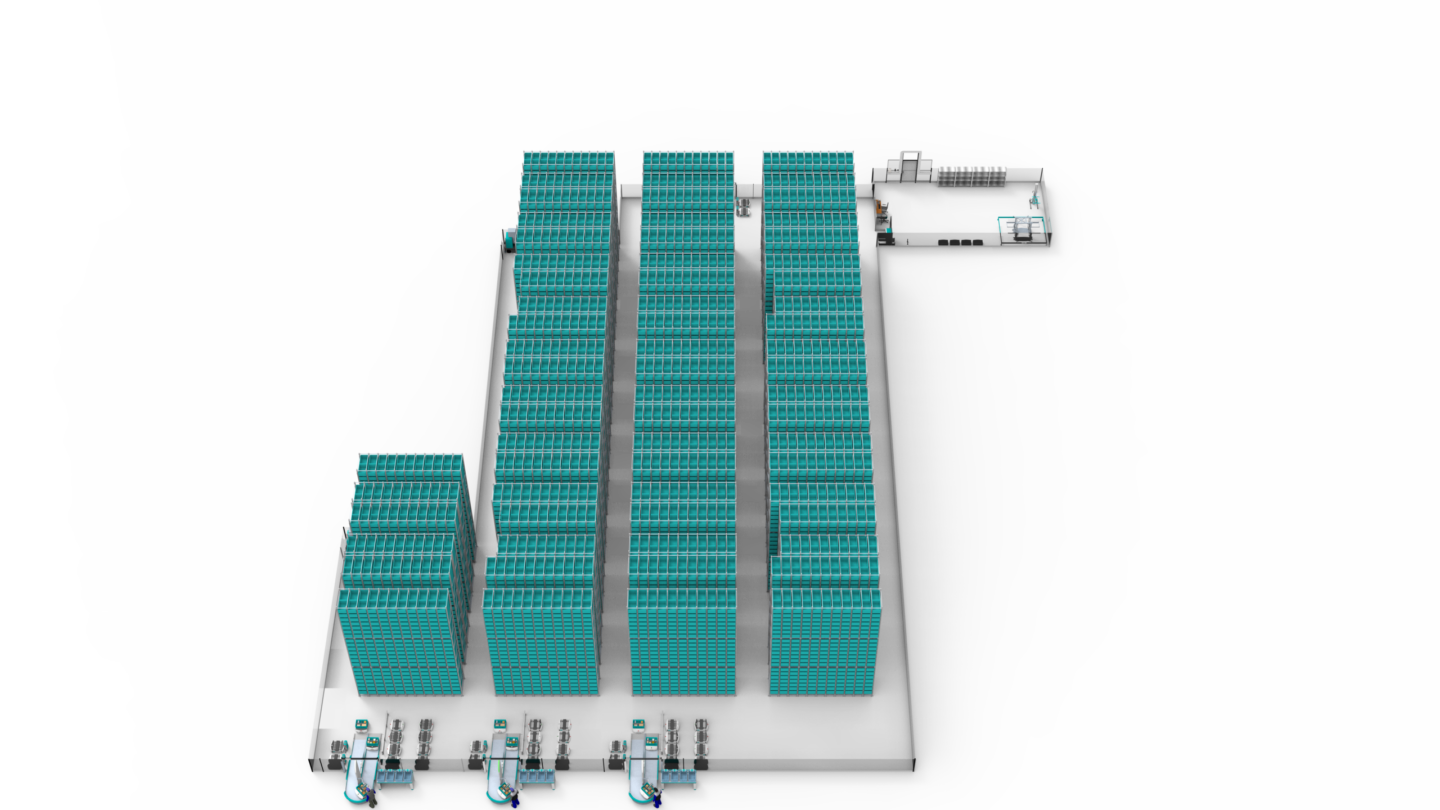

The Skypod System Solution

| Robots | Picking Stations | Replenishment Stations | Storage Bins | Bins/Hour | Rack Height | System Footprint |

| 39 | 3 | 1 | 29,440 | 905 | 9 m (30 ft) | 1,182 m2 (12,730 ft2) |

System integrated by Hy-Tek Intralogistics

Key Results

Game-Changing Performance

- Three ergonomic picking stations capable of processing more than 1,000 order lines per hour with three employees

- Ability to store and pick more than 600,000 items within just 1,182 m2 (12,730 ft2) — less than a quarter of the size of a football field

- System installed on schedule in just seven months after contract signing

- System dimensioned for quick expansion as robots can be added within minutes, stations within days, and storage racks within weeks

“We intend on having a business relationship with Exotec long term. We’re onboarding new business for customers of ours all the time, and we expect to do a lot of work with Exotec in the future. They’ve proven themselves a reliable collaborator.”

Related Case Studies