Industry

Share

GEODIS소개

GEODIS는 선도적인 글로벌 물류 제공업체로, 전 세계 물류 업계 6위에 랭크되어 있습니다.

공급망의 모든 측면에서 최고의 리더로 널리 인정받고 있는 GEODIS는 60여 개국에 직접 진출해 있으며 170여 개국에 걸친 글로벌 네트워크와 49,400명 이상의 직원을 보유하고 있습니다.

이 물류 선도기업은 혁신적이고 지속 가능하며 윤리적인 물류를 통해 전 세계에 상품을 배송함으로써 사람들에게 서비스를 제공하기 위해 최선을 다하고 있습니다.

GEODIS에 대해 자세히 알아보세요 click here.

도전 과제

내슈빌에 위치한 GEODIS의 물류창고는 항상 변화하는 다양한 제품을 취급하는 여러 브랜드의 주문 처리를 담당하고 있습니다.

목표를 달성하기 위해 GEODIS는 고성능의 유연하고 효율적인 주문 처리 시스템이 필요하다는 것을 깨달았습니다.

매일 수천 건의 주문을 처리하는 동시에 긴급한 주문 요청에 대응할 수 있는 고성능 시스템이 필요했습니다.

성수기 및 장기적인 성장에 대한 예측뿐만 아니라 고객의 SKU 변경에 대한 직접적인 인사이트가 부족했기 때문에 GEODIS는 매우 유연한 시스템이 필요했습니다.

체크리스트에서 가장 중요하게 생각한 것은 불필요한 장비에 대한 추가 자본 지출이나 지속적인 운영 중단 없이 처리량과 스토리지 용량을 신속하고 독립적으로 확장하여 현재의 요구 사항을 충족할 수 있는 시스템이었습니다.

GEODIS의 부사장 겸 e물류 총괄 매니저인 Matt Street는 “우리는 항상 고객으로부터 어떤 제품을 받게 될지 구체적으로 알 수 없기 때문에 유연성을 염두에 두고 설계해야 했고, Exotec®은 확실히 그런 기능을 제공했습니다.”라고 말합니다.

지속적인 노동력 부족으로 인해 GEODIS는 수동 주문 피킹과 관련된 힘들고 비효율적인 작업을 자동화할 수 있는 솔루션이 필요했습니다.

이러한 작업에는 매일 먼 거리를 걷거나 무거운 물건을 들어 올리는 작업이 포함되어 있어 직원들에게 많은 시간과 노력이 필요했습니다.

GEODIS는 이러한 문제를 완화할 뿐만 아니라 보다 직원 친화적이고 생산적인 업무 환경을 조성할 수 있는 솔루션을 찾고 있었습니다.

솔루션

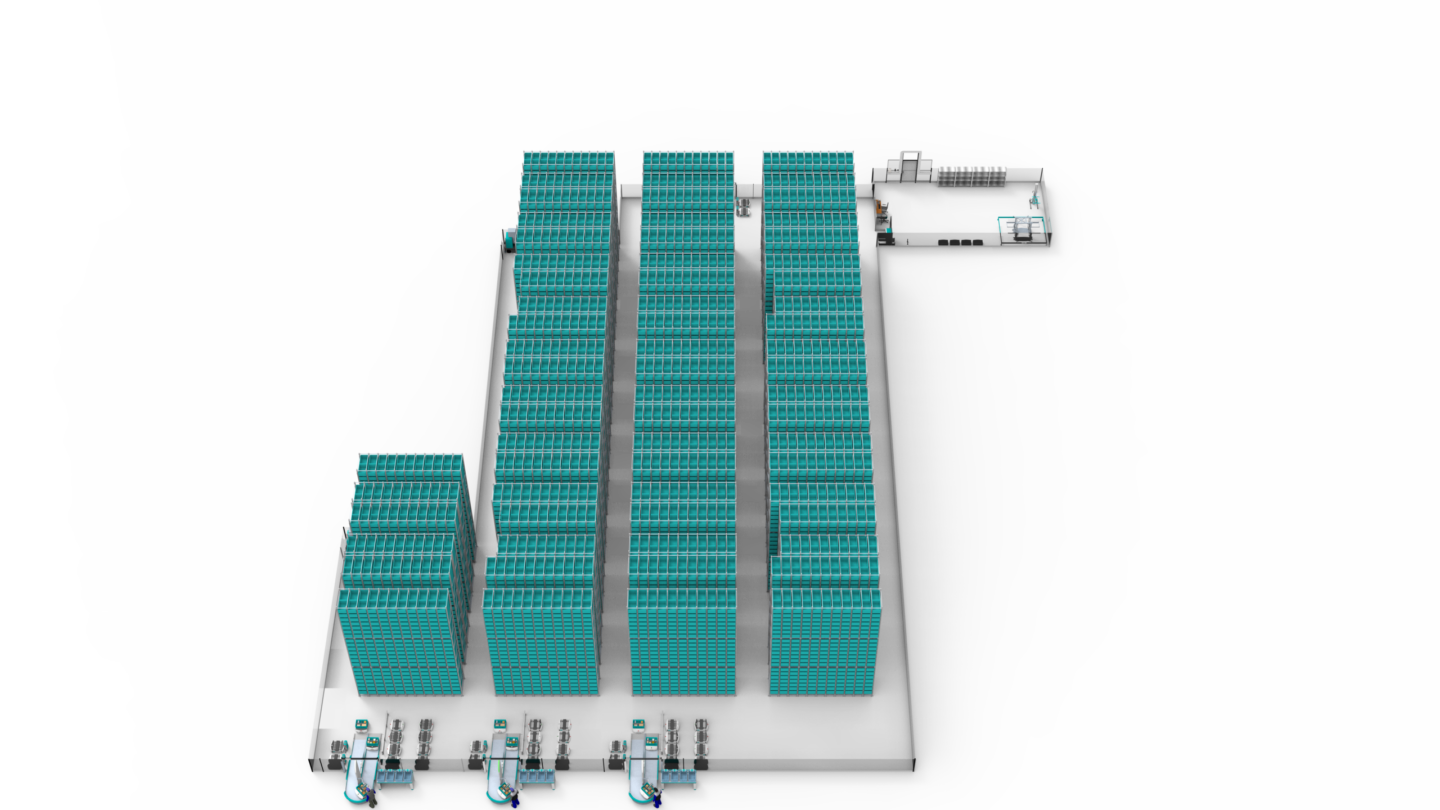

| 로봇 | 스테이션 | 보관함 | 시간당 보관함 수 | 시스템 높이 | 시스템 설치 면적 |

| 39 | 4 | 29,440 | 905 | 9 m | 1,182 m2 |

하이텍 인트라로지스틱스에 의해 통합된 시스템

결과

1. 향상된 성능

- 3명의 직원이 시간당 800개의 빈을 처리할 수 있는 인체공학적 피킹 스테이션 3개를 갖추고 있습니다

- 2분 이내에 시스템 내 모든 SKU에 액세스하여 긴급한 주문 요청을 처리하여 빠른 배송 가능

2. 효율성 향상

- 계약 체결 후 7개월 만에 일정에 맞춰 시스템 설치 완료

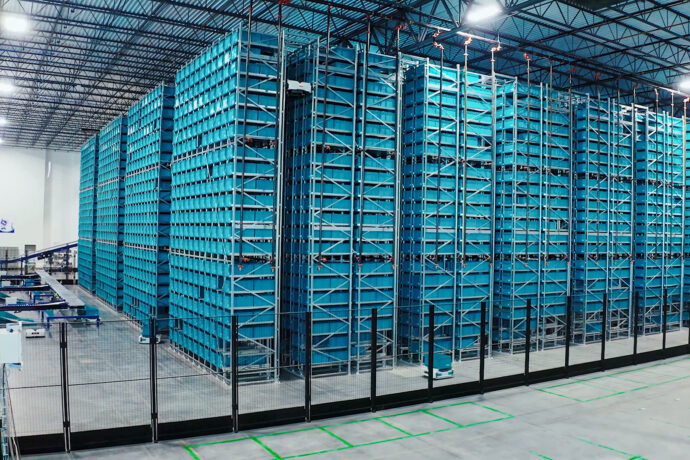

- 30피트 높이의 랙을 갖춘 더블 딥 스토리지로 창고 전체 높이를 활용하여 고밀도 스토리지 제공

- 성수기 수요를 충족하기 위해 몇 분 안에 로봇을 추가로 대여하여 시스템에 추가함으로써 자본 지출을 절감할 수 있습니다.

“엑소텍과 장기적인 비즈니스 관계를 맺을 계획입니다. 우리는 항상 우리 고객을 위해 새로운 비즈니스를 온보딩하고 있으며, 앞으로도 Exotec과 많은 일을 할 수 있을 것으로 기대합니다. 엑소텍은 신뢰할 수 있는 협력자임을 스스로 입증했습니다.”