Industry

Share

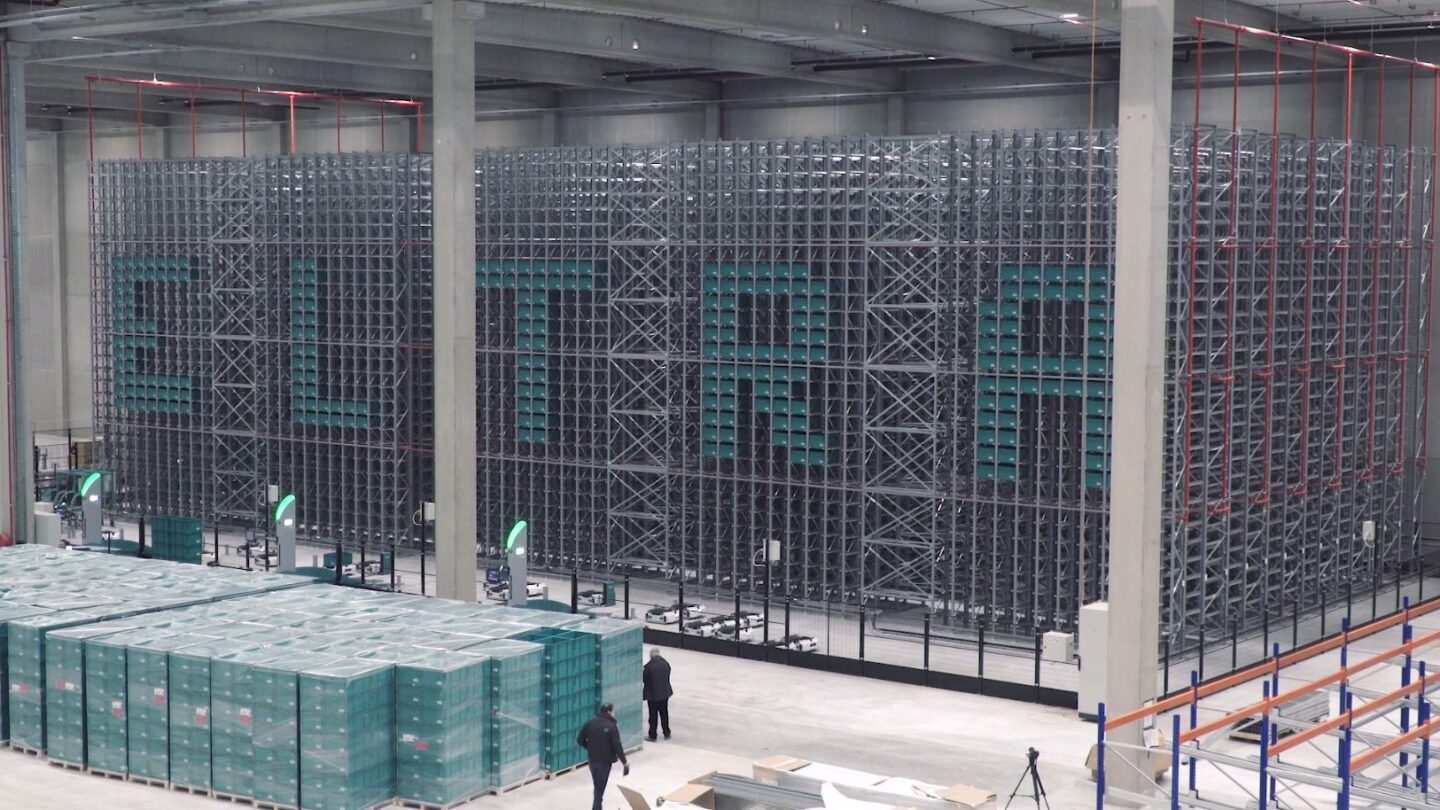

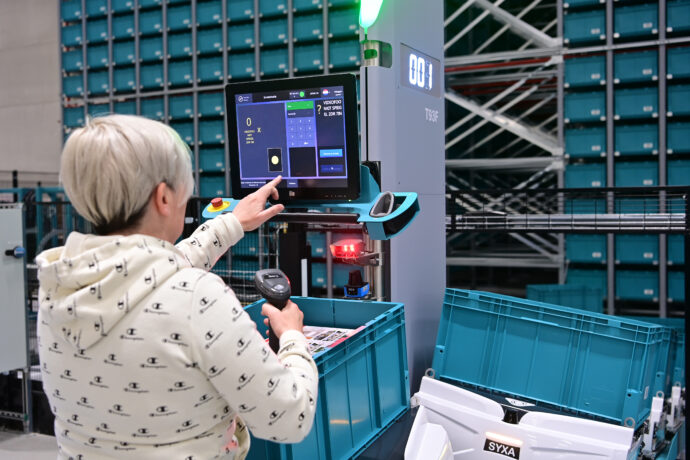

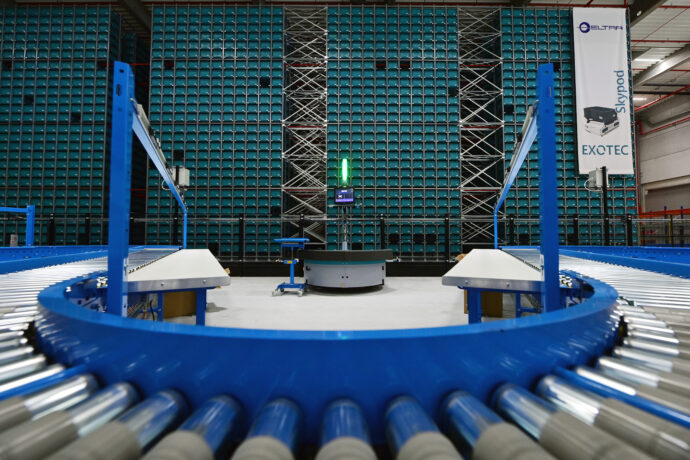

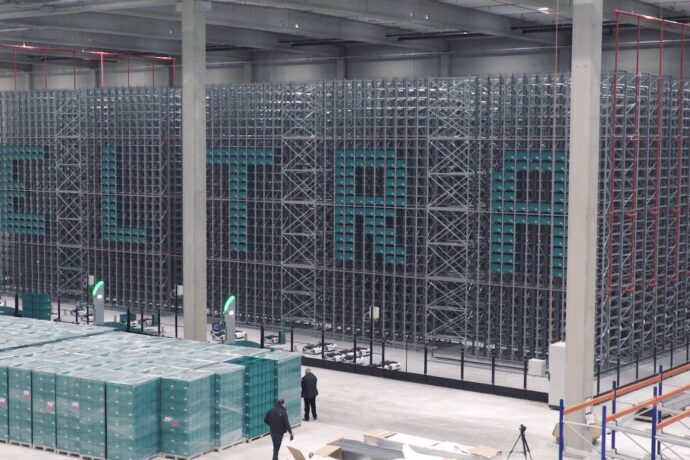

Discover how Exotec® helped Eltra overcome their throughput and storage challenges with an 855 m² (9,200 ft²) Skypod® system, capable of efficiently processing 10,500 order lines daily at just three ergonomic picking stations.

About Eltra

Eltra is a Belgium-based wholesaler of electrical, lighting, and DIY products that distributes goods throughout the Benelux region. They also deliver e-Commerce orders from their intermediaries with an emphasis on fast delivery.

The Challenge

In 2021, Eltra faced a critical challenge as it reached the limits of its storage and order processing capabilities. To overcome this hurdle, the company made a strategic decision to relocate to a larger warehouse, covering 1,020 m2 (11,000 ft2). Eltra’s business involves storing inventory for intermediaries and facilitating direct sales distribution. As a result, they manage more than 6,500 SKUs at any given time that must be readily available for immediate shipment.

Before the relocation, Eltra’s fulfillment operations heavily relied on manual labor, with pickers storing and retrieving inventory among pallets, shelves within two picking zones, and order assembly stations. This labor-intensive process involved pickers traversing several miles daily through a complex maze of shelving, often requiring bending and lifting heavy inventory.

As a rapidly growing enterprise consistently seeking acquisition opportunities, Eltra’s primary goal for the new facility was to implement an all-encompassing fulfillment solution capable of boosting productivity in line with their expanding business and the increasing demands of their customers. Moreover, they sought a solution that could adapt to their evolving business needs and seamlessly integrate with their existing storage system.

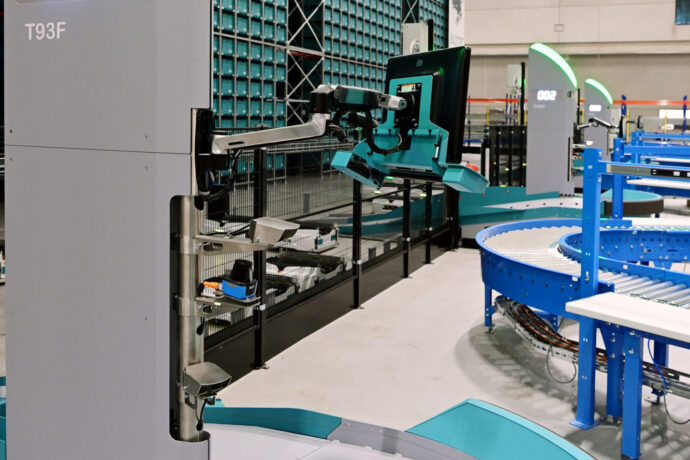

The Skypod System Solution

| Robots | Stations | Storage Bins | Bins/Hour | Rack Height | System Footprint |

|---|---|---|---|---|---|

| 23 | 4 | 20,400 | 600 | 12 m (39 ft) | 855 m² (9,200 ft2) |

Key Results

1. Improved Performance

- Capable of completing up to 10,500 order lines each day at three ergonomic picking stations

- Maximizing space by utilizing full height of warehouse with 12 m (39 ft) tall high-density storage racks

2. Plug & Play Modularity

- Installation completed in just 12 months ahead of schedule with minimal impact to ongoing operations

- Seamless integration with existing storage system to consolidate with manually picked goods

“When I first looked at the system, I thought: this is really a surprise. I’ve been in the logistics industry for 25 years and I’ve never seen a solution like this.”

Related Case Studies