Register for our Next Webinar

Discover the Next Generation of Warehouse Automation — In Your Language

What is a warehouse digital twin? A warehouse digital twin is a virtual model of a physical warehouse system, constructed using digital data to replicate its characteristics and behavior. This technology provides an efficient method for planning, validating, and optimizing warehouse automation, ensuring smooth implementation and long-term reliability.

Harnessing the Power of Digital Twin Technology in Warehouse Automation

While the concept of a digital twin has been a staple in manufacturing, its application in warehouse automation is a more recent yet vital development. Exotec is at the forefront of this shift, utilizing this technology to ensure our customers with the optimal goods-to-person systems for their order fulfillment needs.

In this context, digital twins are indispensable as they facilitate the modeling, simulation, and refinement of warehouse automation processes before system installation. This results in expedited system installation times and ensures operational efficiency. Consequently, these systems are better equipped to adapt to fluctuations in demand and operational loads, offering a robust solution to future uncertainties.

Implementing Digital Twins for Enhanced Warehouse Efficiency

Our digital twin process begins with the digital recreation of our warehouse control system (WCS). This serves as a testing ground for assessing system throughput, warehouse management system (WMS) messaging, and system behavior well in advance of on-site installation.

While these digital models are idealized and do not consider physical variables such as floor conditions or wifi signals, they play a pivotal role in the deployment process. The digital twins not only facilitate thorough testing but also enable the configuration of software settings before the physical installation takes place. This approach extends to simulating maximum capacity operations and WMS API interactions, a critical step in optimizing warehouse efficiency and ensuring preparedness for real-world applications.

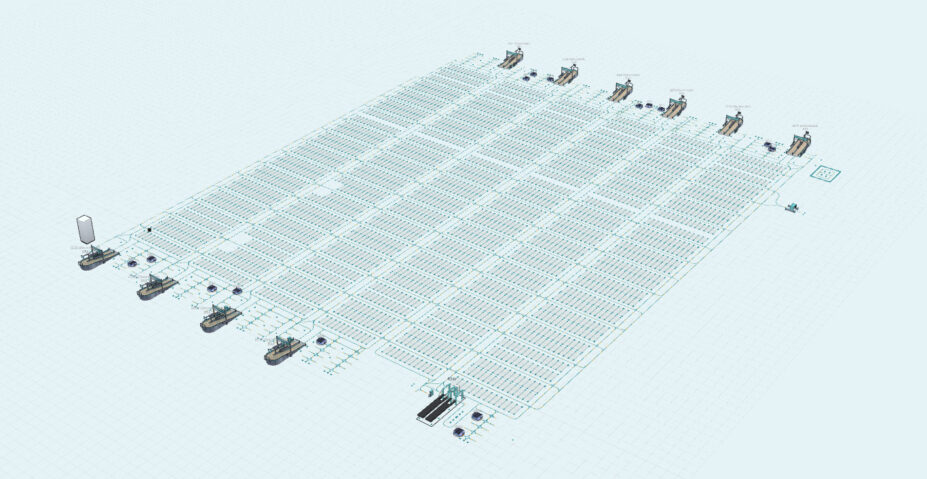

This digital twin of the Skypod system was created by Exotec engineers prior to its installation

The Benefits of a Warehouse Digital Twin

- Scenario Experimentation: Digital twins provide a robust platform for strategic decision-making by enabling in-depth scenario experimentation. Leveraging this technology, we intricately model various configurations of automation, labor distribution, and equipment utilization, gaining profound insights into how each scenario impacts operational efficiency and overall performance. By simulating a variety of “what-if” scenarios involving these characteristics, we can effectively minimize surprises and enhance preparedness for the actual automation implementation.

- Testing Critical Operational Pathways: Digital twins facilitate virtual simulation and analysis of material, information, and resource flow across different pathways, enabling detailed examination of potential inefficiencies or optimization points. This capability is invaluable for ensuring that operational paths are streamlined and resilient.

- Data-Driven Decision Making: Digital twin technology ensures that operational decisions in warehouse automation are thoroughly data-driven and undergo rigorous vetting before implementation. This simulation process allows for a comprehensive analysis of how these alterations might impact key performance indicators, including efficiency, throughput, and resource utilization. Through detailed modeling and scenario testing, decision-makers can make informed choices based on empirical evidence rather than assumptions.

Start Your Journey Towards Advanced Warehousing

Contact us to learn more about how we can ensure your businesses receives the optimal warehouse automation solution.