Industry

Share

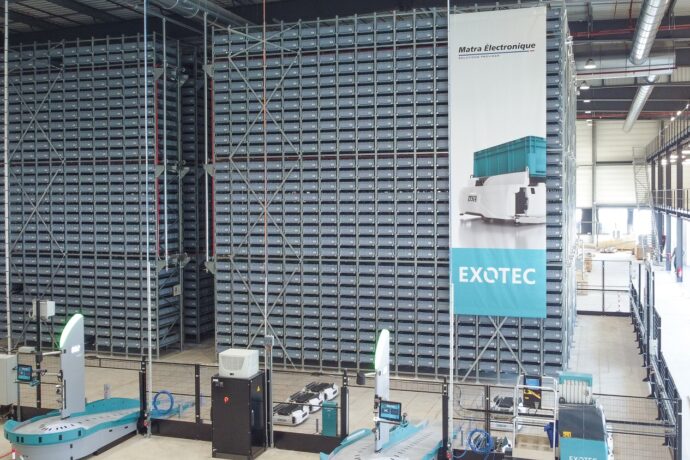

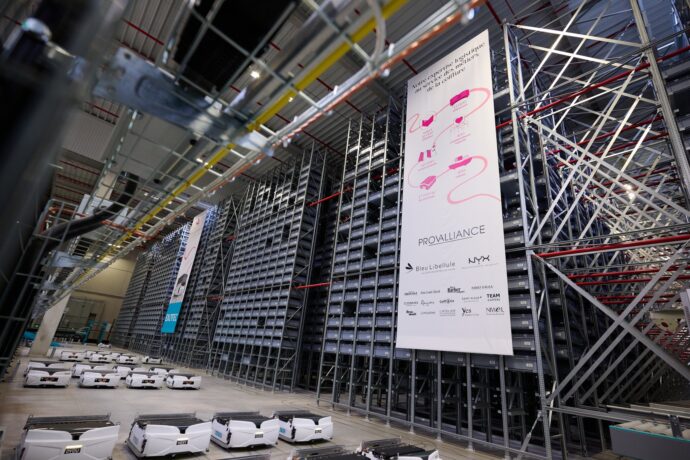

By integrating Exotec® Skypod® system into its warehouse in Gallargues-le-Montueux, CSP – the distribution arm of the Provalliance group (whose commercial brand is Bleu Libellule) – has risen to the challenge of sustained growth while ensuring operational continuity. The objective was to absorb the increase in activity, improve safety and prepare for the future with a scalable, high-performance and ergonomic logistics solution.

About Bleu Libellule and CSP

CSP is the distribution arm of the Provalliance group, the French leader in the distribution of professional hairdressing and beauty products through the Bleu Libellule & Nyx brands, the group’s hairdressing salons and its wholesale partners. The company relies on a network of more than 240 stores, a rapidly growing e-commerce site and in-house logistics. Faced with a continuous increase in volumes, CSP chose to automate part of its warehouse with Exotec, while maintaining its existing operations without any disruption to service.

The challenge

At the start of the project, CSP faced several structural constraints. First, strong and continuous growth was putting pressure on existing facilities. ‘We were really facing very significant growth,’ explains Fabien Levielle, Logistics Director at CSP. The warehouses were full, performance was declining, and the increasing number of people working at the same time was making the site accident-prone. ‘We were using trolleys, preparing orders manually, with lots of people working at the same time and very dense stock… This created an environment that was prone to accidents,’ adds Fabien Levielle.

The priority was to maintain operations while implementing a system capable of increasing productivity within a tight timeframe.

The solution

| Robots | Bins | Bins/h | Stations (with order movers) | Surface au sol |

|---|---|---|---|---|

| 107 | 29,610 | 370 | 7 | 2,000 m2 |

CSP Groupe has dedicated a quarter of its 18,000 m² logistics space to the Exotec installation. The integration was carried out without any disruption to business, as Fabien Levielle points out: ‘We had to distribute the stores without interruption throughout the Skypod system filling phase and the entire transition phase.’

The project required a strong commitment from the internal teams, particularly to ensure the stability and rapid ramp-up of the system, as noted by Susan Marché, logistics engineer at CSP: ‘The system was reliable right from the start. The teams did a great job on that part .’

The project also includes a station system, also integrated by Exotec, dedicated to high-turnover or bulky items. This combination allows for fine-tuning to product profiles and peaks in demand.

1. Density and maintenance of on-site activity

The Skypod system has made it possible to consolidate a large volume of items in a small space, while absorbing business growth. Thanks to this densification, CSP has been able to maintain operations at its historic site, keeping all logistics operations in Gallargues-le-Montueux without having to relocate or add additional warehouse space.

Enhanced safety and ergonomics

Automation has transformed working conditions for teams: coactivity has been reduced, physical journeys have been virtually eliminated and workstations have been redesigned. The result is a sharp drop in the number of accidents, less strenuous daily work and a significant improvement in workplace comfort.

3. Productivity and quality

Overall productivity has doubled for order preparation across all channels. At the same time, inventory control has been strengthened: fewer product breakages, fewer inventory discrepancies and a higher level of reliability throughout the chain.

4. Reliability from the outset

Implementation took place without any disruption to business. The system achieved stable performance within the first few weeks, allowing all warehouse flows to be gradually transferred to the new infrastructure. The project was completed within a short timeframe, with a high level of operational reliability from the outset.

One of the advantages of the Exotec system is its ability to adapt and evolve easily, which is not always the case with more rigid solutions.

Related Case Studies

HARTMANN France modernises its logistics with Exotec’s Skypod system

A new system to combine operational performance, well-being at work and customer service.