Pick and Replenishment Stations for your warehouse

Stations

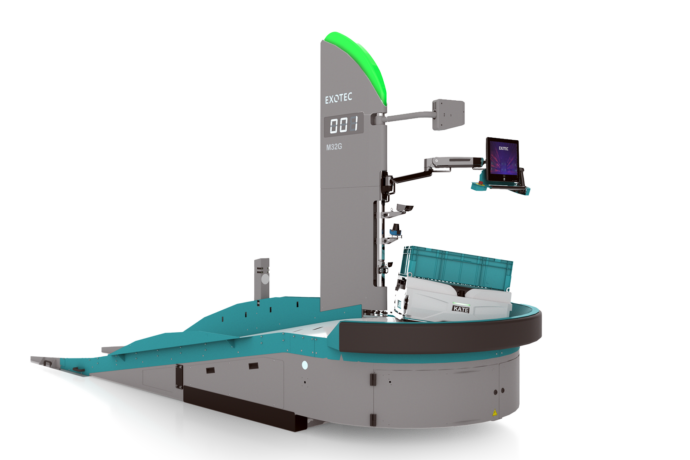

Stations are ideal for smaller systems without a connecting conveyor system or with limited space. They can be used for order picking, inventory replenishment, and inventory checking. The station is made up of a ramp, a screen and various scanners that allow robots with bins and trays to be presented to operators for easy, ergonomic picking of up to 400 lines per hour.

Stations improve working conditions for operators by reducing their need to walk several miles per day. Operators are able to stand in one location while our Skypod® robots travel from the racks to the stations with the items needed for each order.

From the height of the bins and screens to the padded resting pads, everything has been designed to reduce the strain and fatigue of human operators.

To improve your preparation accuracy by adding station accessories like Pick-to-Light, static scanners, or handset scanners.

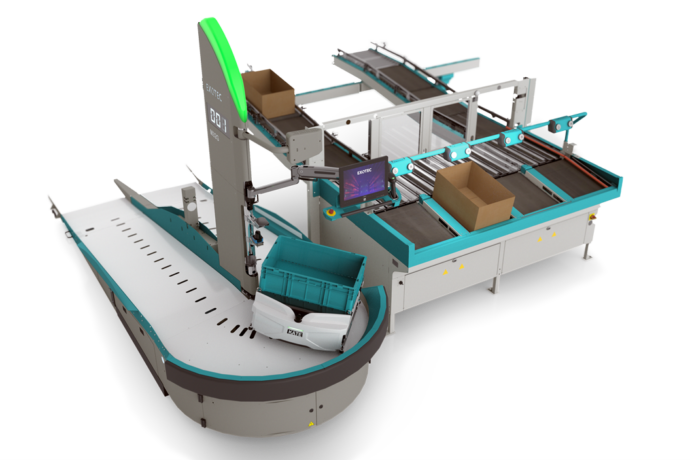

Stations with Order Movers

Stations with Order Movers are ideal for larger systems with conveying systems. These stations combine our standard station to increase productivity and allow operators to prepare up to four orders at once.

Order Movers are located beside our stations, and have four locations for order preparation containers to be cycled through as orders are prepared. The order fulfillment process is streamlined by conveyors that automatically introduce and remove order preparation containers as orders are prepared by operators.

Operators prepare orders using an intelligent Put-to-Light system that assists and indicates which fulfillment container an item should be placed into. Once all goods within an order are placed into the preparation container, the operator presses a button to send the order to the next phase of the order fulfillment process.

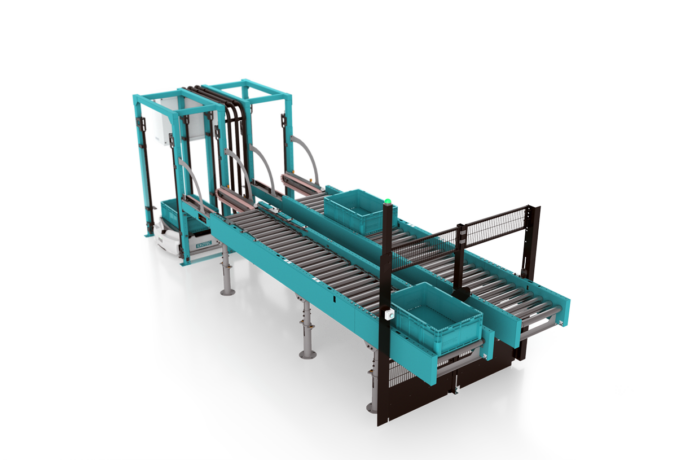

Bin Interface

The Bin Interface automates the entry and removal of bins and trays from the Skypod system. This allows you to easily replenish your system with new stock or buffer prepared orders before they ship from the warehouse.

This type of station ensures a steady flow of up to 320 bins or trays per hour and connects to a conveyor system that leads to the other phases of your order fulfillment process.

Frequently Asked Questions

Operators at the Skypod system stations are equipped with intuitive and efficient tools designed to streamline the order processing workflow and eliminate picking errors. These tools include:

- User-friendly Touchscreens: For easy navigation and interaction with the system.

- Barcode Scanners: To assist in quick and accurate order verification and tracking.

- Pick-to-Light and Put-to-Light Systems: These systems guide operators to the correct items and locations, significantly reducing the possibility of errors and increasing the speed of order fulfillment.

One of the key advantages of our system is its ease of use. Operators can typically be fully trained within just 30 minutes, ensuring a smooth and rapid transition to high productivity.

The stations and the Skypod system are designed to ensure a comfortable and safe working environment. By bringing goods directly to the operators at an ergonomic height, the system minimizes the need for bending, lifting, or excessive movement, thereby reducing the risk of workplace injuries. Additionally, the design of the stations ensures that all necessary tools and interfaces are within easy reach, promoting a better work posture and overall ergonomic experience for employees.

Yes, stations within the Skypod system are adept at handling both piece and case picking. This flexibility is crucial for catering to omnichannel order fulfillment, a wide array of order profiles, and maximizing the efficiency of order fulfillment processes.

In the Skypod system, each station is capable of fulfilling up to four orders concurrently, thanks to the integration of the order mover. This capability significantly enhances the order fulfillment capacity of each station, allowing for a more efficient and productive workflow.